|

|

|

|

Toyo's copper plating contributes to a lot of industry fields using the physicality proper to copper including the conductivity. We have plating equipment for cyanide copper and blue vitriol and have a long-term actual achievement of shape, heavy and large parts that cannot be processed by competitors, so we can assure the reliable processing. |

|

■Main characteristics of copper plating for industrial use

- Electric conductivity: It is adopted for a lot of parts that require the power distribution property and used for the earth cable for preventing the explosion generated from fire of machine components including the electric components.

- Heat conductivity: The copper plating is used for remarkably improving the temperature distribution of significant surface by implementing the thick plating of copper.

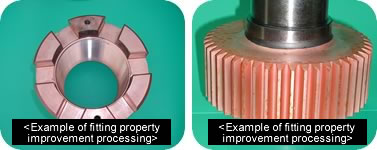

- Fitting property: It is used for preventing the scraping that frequently occurs at the initial operation of machine by implementing the copper plating at the gear part etc.

- High frequency characteristic: The copper plating is used for reducing the transmission loss of high-frequency current of broadcast equipment etc.

- Building-up property: It is implemented for the dimension correction or repair of copper products.

- Carburizing prevention: The copper plating is used as a masking when the hardening is implemented for the necessary part.

- Overcurrent: If the impetus is applied on the copper plating, the current becomes the heat energy and exhales because of the resistance of copper itself. At this time, a lot of tourbillions of current is generated (overcurrent) and it is used for the measurement gauges such as sensor.

[Example of use]

- Various electric components

- Roll of printing machine

- Gear, screw, bolt, nut

- Casing

- Carburizing prevention

- Sensor rod

|

|

|

|

|